Silicon Steel/Electrical Steel Supplier From China —— WUXI ZHONGXIN SPECIAL STEEL

Silicon Steel

Silicon steel, also known as electrical steel, silicon electrical steel, lamination steel, relay steel, or transformer steel is specialty steel with silicon added to it, which improves its electrical resistivity and magnetic properties, and reduces hysteresis loss. This steel is ideal for various electrical applications where electromagnetic fields are important, such as transformers, magnetic coils, and electrical motors.

Electrical steel usually referred to as cold-rolled electrical steel, can be divided into two major categories including grain-oriented electrical steel and non-oriented electrical steel. Grain-oriented electrical steel, with its easy magnetization direction parallel to the rolling direction, has excellent magnetic properties in this direction including low core loss, high permeability, and low magnetostriction, and is widely used in the transformer industry. Further, it can obtain lower core loss by domain refinement treatment. Meanwhile, non-oriented electrical steel, featured by a random distribution of grain orientation and magnetic isotropy, is widely applicable to the motor industry.

Non-oriented electrical steel usually contains a level of 2%-3.5% silicon. It has similar magnetic properties in all directions, the so-called isotropy. Grain-oriented electrical steel usually contains a level of 3% silicon and is processed in a way to develop ideal properties in the rolling direction. Cold-rolled non-grain-oriented steel (CRNGO) is less expensive than cold-rolled grain-oriented steel (CRGO). CRNGO can be used in cost-oriented applications with the inconstant direction of magnetic flux, such as electric motors and generators. CRGO is usually in coil form and has to be cut into laminations further, being used in transformer core applications, such as certain internal parts in audio output transformers.

Silicon Steels and Their Applications

Silicon steel is the most important magnetic material in industrial applications. The general applications include volt relays or pulse transformers from the generator, automotive, and transformer sectors.

Silicon steel is undoubtedly the most important soft magnetic material in use today. Applications vary in quantities from the few ounces used in small relays or pulse transformers to tons used in generators, motors, and transformers. Continued growth in electrical power generation has required development of better steels to decrease wasteful dissipation of energy (as heat) in electrical apparatus and to minimize the physical dimensions of the increasingly powerful equipment now demanded.

Substantial quantities of oriented steel are used, mainly in power and distribution transformers. However, it has not supplanted nonoriented silicon steel, which is used extensively where a low-cost, low-loss material is needed, particularly in rotating equipment. Mention should also be made of the relay steels, used widely in relays, armatures, and solenoids. Relay steels contain 1.25 to 2.5% Si, and are used in direct current applications because of better permeability, lower coercive force, and freedom from aging.

Important physical properties of silicon steels include resistivity, saturation induction, magneto-crystalline anisotropy, magnetostriction, and Curie temperature.

Making and Using Oriented Steel

Oriented silicon steel is more restricted in composition than non-oriented varieties. The texture is developed by a series of careful working and annealing operations, and the material must remain essentially single-phase throughout processing, particularly during the final anneal because phase transformation destroys the texture. To avoid the y loop of the Fe-Si phase system, today`s commercial steel has about 3.25% Si. Higher silicon varieties, which might be favored on the basis of increased resistivity and lower magnetostriction, are precluded by difficulties in cold rolling.

Temperature, atmosphere composition, and dew point are closely controlled to decarburize the strip without oxidizing the surface. During this treatment, primary recrystallization occurs, forming small, uniform, equiaxed grains. The coating of magnesium silicate glass which forms will provide electrical insulation between successive laminations when assembled in a transformer core. At this stage, the steel is graded by cutting Epstein samples from the coil; the samples are stress relief annealed and flattened at 790°C, and tested for core loss.

Oriented silicon steel material contrast table | Non-oriented silicon steel material contrast table | ||||||||||||||||||

列 | 公称厚度 | 宝钢 | 武钢 | 新日铁 NSC | JFE | Congent | 蒂森克虏伯 | 浦项 Posco | 新利佩茨克 | 阿姆可 AK | 公称厚度 (mm) | 宝钢 | 新日铁 | JFE | 蒂森克虏伯 | 浦项 | 新利佩茨克 | 阿姆可 | |

Normal | 0.23 | B23G110 | 23Q105 | 0.35 | B35A210 | 35H210 | 35JN210 | M210-35A | 35PN210 | ||||||||||

23Q110 | 23Z110 | C110-23 | NV23S - | B35A230 | 35H230 | 35JN230 | M235-35A | 35PN230 | |||||||||||

23Q115 | B35A250 | 35H270 | 35JN250 | M250-35A | 35PN250 | 2413 | M- 15 | ||||||||||||

B23G120 | M120 - | C120-23 | NV23S - | M-3 | B35A270 | 35H270 | 35JN270 | M270-35A | 35PN270 | 2412 | M- 19 | ||||||||

M127 - | C127-23 | NV23S - | B35A300 | 35H300 | 35JN300 | M300-35A | 35PN300 | 2411 | M-22/M-27 | ||||||||||

0.27 | 27PG110 | NV27S - | B35A360 | 35H360 | 35JN360 | 35PN360 | |||||||||||||

B27G120 | 27Q120 | 27Z120 | 27JG120 | C120-27 | 27PG120 | NV27S - | M-4 | B35A440 | 35H440 | 35JN440 | 35PN455 | ||||||||

B27G130 | 27Q130 | 27Z130 | 27JG130 | M130 - | C130-27 | 27PG130 | NV27S - | M-4 | B35A550 | 35PN560 | |||||||||

27Q140 | M140 - | C140-27 | NV27S-14 | 0.5 | B50A230 | 50H230 | 50JN230 | M230-50A | 50PN230 | ||||||||||

0.3 | 30PG110 | B50A250 | 50H250 | 50JN250 | M250-50A | 50PN250 | |||||||||||||

B30G120 | 30Q220 | 30Z120 | 30JG120 | 30PG120 | NV30S - | B50A270 | 50H270 | 50JN270 | M270-50A | 50PN270 | 2414 | ||||||||

B30G130 | 30Q180 | 30Z130 | 30JG130 | C130-30 | 30PG130 | NV30S - | B50A290 | 50H290 | 50JN290 | M290-50A | 50PN290 | 2413 | M- 15 | ||||||

B30G140 | 30Q160 | 30Z140 | 30JG140 | M140 - | C140-30 | 30PG140 | NV30S - | M-5 | B50A310 | 50H310 | 50JN310 | M310-50A | 50PN310 | 2412 | M- 19 | ||||

30Q150 | M150 - | C150-30 | M-5 | B50A350 | 50H350 | 50JN350 | M350-50A | 50PN350 | M-22 | ||||||||||

30Q140 | B50A400 | M400-65A | 50PN400 | M-27/M- 36 | |||||||||||||||

30Q130 | B50A470 | 50H470 | 50JN470 | M470-50A | 50PN445 | 2214 | |||||||||||||

30Q120 | B50A600 | 50H600 | 50JN600 | M600-50A | 50PN595 | 2212 | |||||||||||||

0.35 | B35G135 | 35Q135 | 35Z135 | 35JG135 | NV35S - | B50A700 | 50H700 | 50JN700 | M700-50A | 50PN760 | M-47 | ||||||||

B35G145 | 35Q145 | 35Z145 | 35JG145 | M150 - | C150-35 | 35PG145 | NV35S - | M-6 | B50A800 | 50H800 | 50JN800 | M800-50A | 50PN890 | 2011 | |||||

B35G155 | 35Q155 | 35Z155 | 35JG155 | M165 - | C165-35 | 35PG155 | M-6 | B50A1000 | 50H1000 | 50JN1000 | M940-50A | 50PN1015 | |||||||

High | 0.23 | B23P090 | 23QG090 | 23ZH090 | 23JGS090 | M90 -23P5 | H090-23 | 23PH090 | B50A1300 | 50H1300 | 50JN1300 | M1100-50A | 50PN1270 | ||||||

B23P095 | 23QG095 | 23ZH095 | 23JGS095 | H095-23 | 23PH095 | 0.65 | B65A470 | M470-65A | 65PN470 | M-43 | |||||||||

B23P100 | 23QG100 | 23ZH100 | 23JGH100 | M100 - | H100-23 | 23PH100 | H-0 | B65A600 | M600-65A | 65PN595 | M-45 | ||||||||

23ZH110 | B65A700 | M700-65A | 65PN760 | ||||||||||||||||

0.27 | H090-27 | B65A800 | 65JN800 | M800-65A | 65PN890 | M-47 | |||||||||||||

B27P095 | 27QG095 | 27ZH095 | H095-27 | 27PH095 | B65A1000 | 65JN1000 | M1000-65A | 65PN1015 | |||||||||||

B27P100 | 27QG100 | 27ZH100 | 27JGH100 | M103 - | H103-27 | 27PH110 | NV27P- | B65A1300 | 65JN1300 | M1300-65A | 65PN1270 | ||||||||

B27P110 | 27QG110 | 27ZH110 | 27JGH110 | H-1 | |||||||||||||||

0.3 | B30P100 | 30QG100 | 30ZH100 | 30JGH100 | 30PH100 | ||||||||||||||

B30P105 | 30QG105 | 30ZH105 | 30JGH105 | M105 - | H105-30 | 30PH105 | NV30P- | ||||||||||||

B30P110 | 30QG110 | 30ZH110 | 30JGH110 | M111 - | H111-30 | ||||||||||||||

B30P120 | 30QG120 | 30ZH120 | 30JGH120 | M117 - | |||||||||||||||

0.35 | B35P115 | 35ZH115 | 35JGS115 | 35PH115 | |||||||||||||||

B35P125 | 35ZH125 | 35JGS125 | 35PH125 | ||||||||||||||||

B35P135 | 35ZH135 | 35JGH135 | 35PH135 | ||||||||||||||||

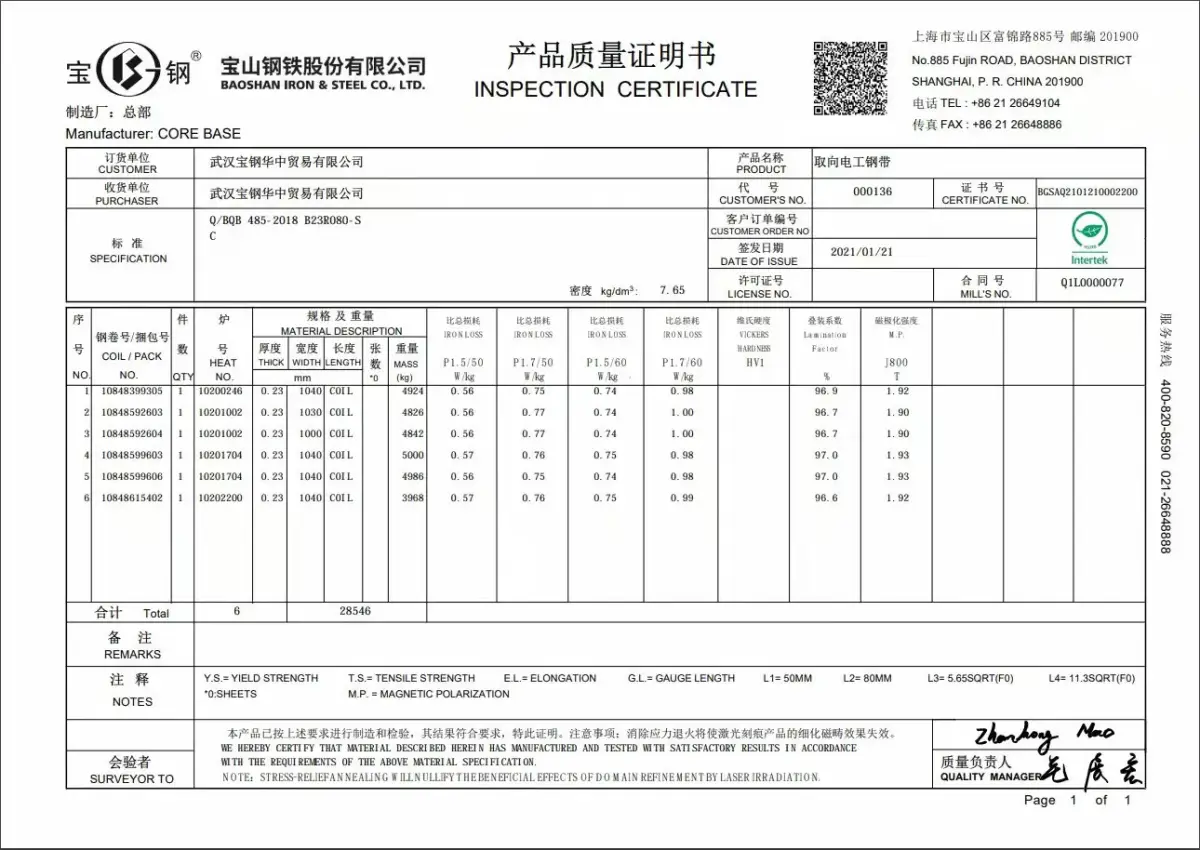

High | 0.23 | B23R080 | 23ZDKH80 | 23JGSD80 | 23PHD080 | ||||||||||||||

B23R085 | 23ZD0KH85 | 23JGSD85 | H085-23 | 23PHD085 | |||||||||||||||

B23R090 | 23ZD5KH90 | 23JGSD90 | H090-23 | H-0DR | |||||||||||||||

0.27 | B27R090 | 27ZD0KH90 | 27JGSD90 | H090-27 | 27PHD090 | ||||||||||||||

B27R095 | 27ZD0KH95 | 27JGSD95 | 27PHD095 | H-1DR | |||||||||||||||

Product Specification and Size :

Standard Size

Thickness | Width | Slitting | Inside Diameter | Outside Diameter |

0.23/0.27/0.3/0.35mm | Original: 750~1290mm | 40~645mm | 508~610mm | 800~1550mm |

Fields of Application

Fields of application | Grain-oriented electrical steel | Non-oriented electrical steel | |||||||||

Series G | Series P | Series R | Series A | Series AH | Series AR | Series AT | |||||

230~400 | 440~700 | 800~1300 | 230~470 | 600~1000 | |||||||

Rotators | Large-sized motors | √ | √ | ||||||||

Medium-sized motors | √ | √ | √ | ||||||||

Compressor motors | √ | √ | √ | √ | √ | √ | |||||

General motors | √ | √ | √ | √ | √ | √ | |||||

Small-sized precision motors | √ | √ | √ | √ | √ | √ | |||||

Motors for electric cars | √ | √ | √ | √ | |||||||

Static device | High-frequency motors | √ | √ | √ | |||||||

Large-sized transformers | √ | √ | √ | ||||||||

Small-sized power transformers | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

Transformers for instruments | √ | √ | √ | ||||||||

Reactors and magnetic amplifiers | √ | √ | √ | √ | |||||||

Power switches | √ | ||||||||||

Transformers for welding | √ | √ | √ | ||||||||

Voltage regulators | √ | √ | √ | √ | √ | √ | |||||

Magnetic sealers | √ | √ | √ | √ | |||||||

Electromagnetic devices for accelerators | √ | √ | √ | √ | |||||||

-Material Selection

Grain-oriented electrical steel

Varieties | Common type | High induction type | Domain refinedhigh induction type |

Large motors | √ | √ | |

Large transformers | √ | √ | √ |

Medium and small transformers | √ | √ | √ |

Distributing transformers | √ | √ | |

Voltage regulator | √ | √ | √ |

Reactor and magnetic amplifier | √ | √ | |

IF transformer | √ | ||

Mutual inductor | √ | √ | |

TV transformer | √ | √ | |

Radio transformer | √ | √ | |

Radio broadcast transformer | √ |

Insulating Coating

Insulating Coating | ||

Coating types | M11 | M21 |

Component | Chromium containing , semi organic coating | Chromium free, semi organic coating |

Coating thickness(μm) | 0.7~1.5 | 0.8~5.0 |

Interlayer resistance(Ω•mm2 /slice) | ≥100 | ≥100 |

Adhesive property | Class A or class B | Class A or class B |

Punching property | Excellent | Excellent |

Antirust property | Excellent | Excellent |

Heat resisting property | Resistant annealing at 750 C, N2 protection, for 2h | Annealing resistance in general |